Titanium – Zirconium – Niobium composites

Our Titanium, Zirconium, or Niobium composites production process is a highly controlled process, made under high pressure in a protective atmosphere. The resulting product is a homogeneous composite that you can use for various applications in knifemaking, watchmaking, or jewelry applications. Main properities of our non-ferrous composites:

Corrosion resistance – Our composites are highly corrosion resistant even when they are in a long-time contact with human skin or exposed to the most commonly available acids.

Hypoallergenity – Due to their composition, our materials are fully hypoallergenic, they can be worn on various places of a human body without risk of skin irritation.

Low weight – important issue, especialy for a long time wearable stuff. Titanium composites reach at least one-half of a steel weight (ρ = 4,5 g/cm3) even in composition with Zirconium, we get low-weight (ρ = 4,99 g/cm3).

Colours – our composites are rich in color composition you can reach by heat or electrochemical oxidation. This gives you a chance for many colour combinations, however black and white is also possible when Titanium-Zirconium composite is used.

Moku-Ti – #CompositeFuturon

is a of various titanium grades (mainly Gr2, Gr5, Gr7, Gr9). The resulting composite is lightweight (ρ = 4,5 g/cm3). #CompositeFuturon has perfect mechanical properties, and it’s rich in color combinations. You can reach different colors by electrochemical or heat oxidation. Each piece of produced material can be colored differently depending on possible anodizing colour-spectrum. Material is fully hypoallergenic. It’s suitable for knifemaking, jewelry applications, or watchmaking. We make this material in various shapes, mainly flat bars, rods, or bolster mosaics.

Zircu-Ti – #BlackFuturon

a composite of Zirconium and various Titanium grades (mainly Gr2, Gr5, Gr7, Gr9). Zirconium (Zr) is an extremly corrosion-resistant metal. When heated, it takes black oil color. Depending on percentage of Zirc in composition is material a bit heavier than full-Titanium damascus (ρ = 4,99 g/cm3). You can reach different colors by electrochemical or heat oxidation. Each piece of produced material can be colored differently depending on possible anodizing color spectrum. Material is entirely hypoallergenic. It’s suitable for knifemaking, jewelry applications, or watchmaking. We make this material in various shapes, mainly flat bars, rods ,or bolster mosaics.

Technical information

Composition

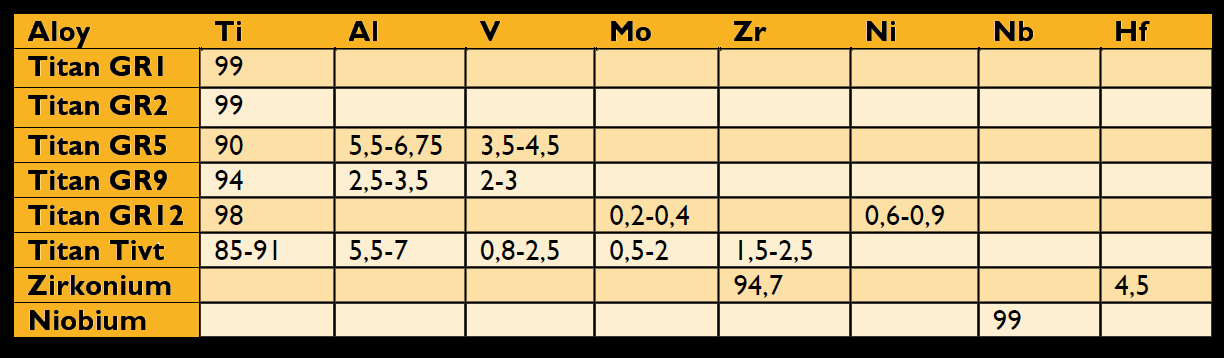

Chemical composition of our mainly used non-ferrous materials

Machining conditions

For proper machining of our composites, it is good to have some skill in the machining of Titanium. In composition with Zirconium or Niobium, machining is a bit more complicated than with Titanium composite. For unskilled users, we recommend making a sample piece and finding the machining conditions matching their equipment. Our recommended machining conditions below:

• Milling – monolithic carbide mill — Vc40 m/min

• For hard-milling (sizing) with monolithic carbide, mill feed up to Vc60 m/min

• Milling with VBD mill — Vc40 m/min

• Lathing with VBD mill — Vc40 m/min

• Milling with HSS-Co mill — Vc10 m/min

• Drilling – HSS-Co drill — Vc6-8 m/min

• Drilling – PVD coated carbide drill —Vc27-45 m/min

Grinding

Our composites can be ground on all conventional types of grinders. We recommend belt-grinders or Berger grinding machines. For belt grinders, we recommend sanding belts with ceramic grains, like 3M Cubitron II. However, all range of conventional abrasives is usable (for example, SAIT, Klingspor, Norton, VSM, etc.). Always use „fresh“ sharp grinding belts – avoiding of creation of burned surface „crust“, which can make problems when coloring.

Polishing

You can get slightly different color results when your product is shiny polished or dimmed. For polishing, we recommend blue Unipol paste. For dimming, we use excellent ScotchBrite belts or pads.

Coloring

You can reach different colors by using heat oxidation (mainly by gas torch), electro-chemical oxidation (using DC electrical source) or combination. For unskilled users, we recommend making some testing samples before you start to color your final product.

Heat oxidation

It is an easiest way to get your composite colors. We recommend using propane butane gas torch and slowly heating the product, starting to reach the first colors. Stop heating when you’ve reached your estimated combinations and let the product slowly cool down. You can reach the first color about 430°C up to 850°C.

Hint: Reaching a dark-black colour on Zirconium composite you have to heat it up to titanium’s purple. When you need a blue-black combination, you have to polish, dimm, or etch a purple color from Titanium (black Zirconium will stand still). Now you have a silver-black variety, and you can make the heat oxidation again (blue is one of the first color).

Electro-chemical oxidation

You can color our material also by using a DC electric source. For reaching a full spectrum of colors you need DC 0-120V. As an electrolyte, use the following solution: 1litre of distilled water + 5 grams of Trisodium phosphate (Na₃PO₄) known as TSP. Instead of TSP you can use 10 grams of baking soda; however, you’ll reach better color results with TSP. Like a cathode, use a piece of Titanium sheet. To dive a product into an electrolyte, use a Titanium or Niobium wire, avoid contact with steel (on a crocodile clip).

• The resulting color combination is different than when you use heat oxidation

• For better color results, use TitanEtch of Multietch as a primer.

• You can use heat oxidation after electro-chemical oxidation – this will bring you new color combinations and deeper colors.

• Using TitanEtch of Multietch, you can remove anodized colors and make other color combinations, especially with black Zirconium.

• Make testing samples before you start to color your final product, especially when you combine heat and electro-chemical oxidation with above-mentioned etchants.